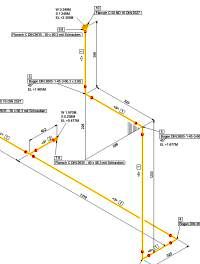

Inter-Disciplinary Check - As piping system will be connected to instrumentations and equipments that are manage by other departments, it is important to ensure that the connections are connectable as an example if in the P&ID the equipment's nozzle size is 10", but actual equipment bought built with nozzle size 12" piping has to accomodate the new size by providing 12" flange, gasket and necessary boltings. Elbows and pipe length can be estimated by pre-route the piping layout into General Arrangement of Equipment and Plan Layout (that shows the whole deck and elevation).Ģ. And from there we could also plan for our purchasing time for long lead items like valves, large bore pipes or special material items. We could estimate how many MTO are required for actual system to be built. Material Take-Off - MTO is crucial for cost estimation especially during bidding stage. Below image shows the common symbols used in P&ID ġ.

The more you go through the P&ID, the easier it will get. If you able to understand the symbols given and understand how the symbol constructed, there should be no problem in reading P&ID.Īll the symbols and acronyms have its legend to elaborate more on what the symbols/ acronyms represent. Just follow through one line from its starting point (like from wellhead) at one page till the end (like flare) that might continued at another page(s).

I believe anyone would be able to read a P&ID as long as they have a good imagination and attention span. Scope of work vendor-contractor interface (if any).Vents and drains except the one required for hydrotesting.Mechanical equipments with its identification tag numbers and nozzles rating.Intrumentations and its identification tag numbers.Valves and its identification tag number.Line number which you could define pipe sizes, system, and materials.Usually P&ID comes with the information of It might be shown very straight short line in P&ID and yet it is a long winding piping system in real world. It shows almost all of the piping material take-off (MTO) except for the elbows and length of pipes. This diagram is like a master document for everything we are going to build in piping system. P&ID is a non-proportional and not-drawn-to-scale schematic illustration that shows process flow of a piping system, connected with instrumentations and system equipments.

0 kommentar(er)

0 kommentar(er)